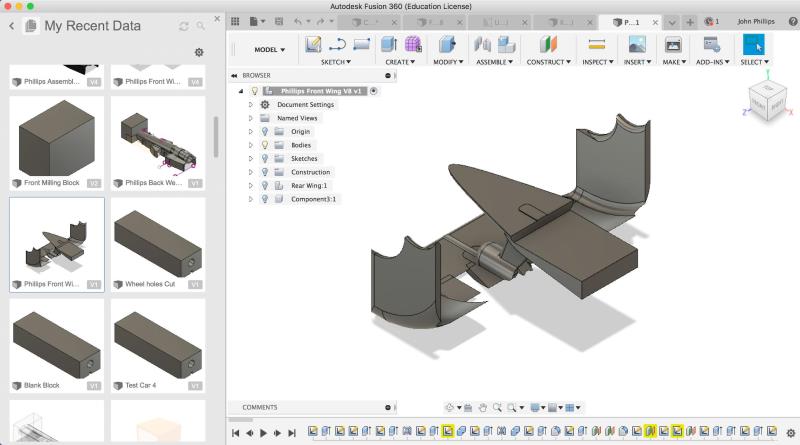

An example of a Fusion 360 model (a front wing for an F1 in Schools car), ready to be printed.

Senior Parramatta Marist students (Year 10 to 12) now have the ability to 3D print directly from their laptops via the school network.

Previously, 3d printing was only possible by logging a job with the Hive (Our STEM Makerspace). Students will now be trusted to use industry standard machines to extend their projects and provide new opportunities for learning.

To get started, students have been emailed a link to a tutorial. They’ll need to download the free MakerBot software, create a printer profile before arranging their objects on a virtual print bed. Once at school, students will be able to use the network to watch a live stream from inside each printer to see which print bed is empty.

Students will be able to adjust the print settings to meet their needs or to test the capabilities of the machines for future projects. Through onboard cameras, student will be able to watch as the print begins to ensure that the PLA filament sticks to the print bed. A countdown timer will allow students to anticipate when they’ll be able to visit the Learning Centre to remove their print from the print bed.

But how do students make the 3D files? Across TAS and STEM subjects, a 3D modelling program called Fusion 360 is being used. It’s free to download and has tools and features which help create complex shapes with control and accuracy. Fusion 360 is a parametric modelling program, meaning that we’re able to assign objects with real-world behaviours. This helps with project involving moving parts, aerodynamics, density and mass calculations. Over time, students will become familiar with the software so that the process of modelling isn’t a barrier to creating whatever they can imagine, model, prototype and propose.

We hope that the possibilities being offered help foster exploration and aspiration.

Fortior Ito

A view from the 3D printer’s onboard camera.

-

01 Jul 2025

Try a Career Day @ CathWest Loyola Campus

Year 10, are you curious about trying a career...? Register for our 'Try a Career Day' at the CathWest Loyola Campus!24 Jun 2025

Try a Career Day @ CathWest McCarthy Campus

Year 10, are you curious about trying a career...? Register for our 'Try a Career Day' at the CathWest McCarthy Campus!